Marine AC Sales AC Repair & AC Maintenance

We Sell, Repair and Do Custom Installs of Marine AC and Refrigeration in the Houston, TX Area.

Preventive Maintenance and Causes of AC Failure

One of the most frequent AC failures is a HPF, HHH, code which means “High Pressure Fault” caused by excessively high gas pressure on the discharge line of your marine AC unit. This happens in most cases because of lack of cooling water flowing through the condenser coils and not cooling down the super heated gas after passing through the compressor.

Sea Strainer Cleaning

1) To prevent shut down of the AC unit from a HPF it is best to clean the sea water strainer for the AC cooling water at regular intervals. In the Clear Lake Area in the summer when water temperature can reach as high as 90 degrees, more frequent cleaning may be required if the unit is running 24/7. High summer water temps cause more growth, which traps and holds the silt. This can mean monthly cleaning or even more frequent cleanings for the AC sea strainer.

It can vary depending on where the vessel is docked. It happens less frequently in the winter months when the water is cooler and temperature is not so hot and the AC is running less. It is best to inspect and clean on a schedule.

Example of type of critter that can clog a line!

System Flush

2) There can also be a buildup of silt inside the cooling coils. The unit may need to be flushed using dockside water by disconnecting the plumbing to clean it so transfer of heat can be increased and lower the operating pressures.

On large yachts that have multiple units run by one pump and using a manifold system to feed the multiple units there is usually one AC unit that gets less water flow than the others. Slow water flow will cause the silt to build up quicker and even though the water flow looks the same as usual it can still go into HPF code and shut down.

Air Filter Cleaning

3) Dirty filters restrict air flow and affect the performance of the system and may cause freezing of condensate on evaporator coils. Monthly cleaning of air filters is recommended.

Shore Power Cord Inspection

4) Inspect shore power cords. Heavy current loads from AC usage and other appliances combined with corrosion and loose connections can cause high resistance and extreme heating of connections and will fail. Regular inspection of shore cord connections is recommended.

Condensate Pan Inspection

5) It is important to periodically inspect the condensate pan for proper drainage. With the AC running and dehumidifying the air, it removes moisture that collects on the evaporator coils and drips into the

condensate pan and then drains off to a sump or sometimes the bilge and is pumped overboard. This is can amount to several gallons per hour. If not draining properly can cause damage to the area around the AC unit and corrosion on the unit itself.

TNT Yacht Repair Offers A Preventive Maintenance Service and Scheduling For your Marine AC Units.

This includes but not restricted to,

- Inspection of AC Temps of Return air and Supply.

- Cleaning of sea strainer.

- Clean air filter.

- Back flush and flush water supply hoses and condenser coils.

- Connect Gauges and check system pressures and Freon levels using the

Superheat Method as recommended by the factory. Add refrigerant if needed. - Check for visible refrigerant leaks. ( oil )

- Check ducting for leakage repair if needed.

- Inspect water flow and condenser coil temps.

This service will help keep your system running it’s best

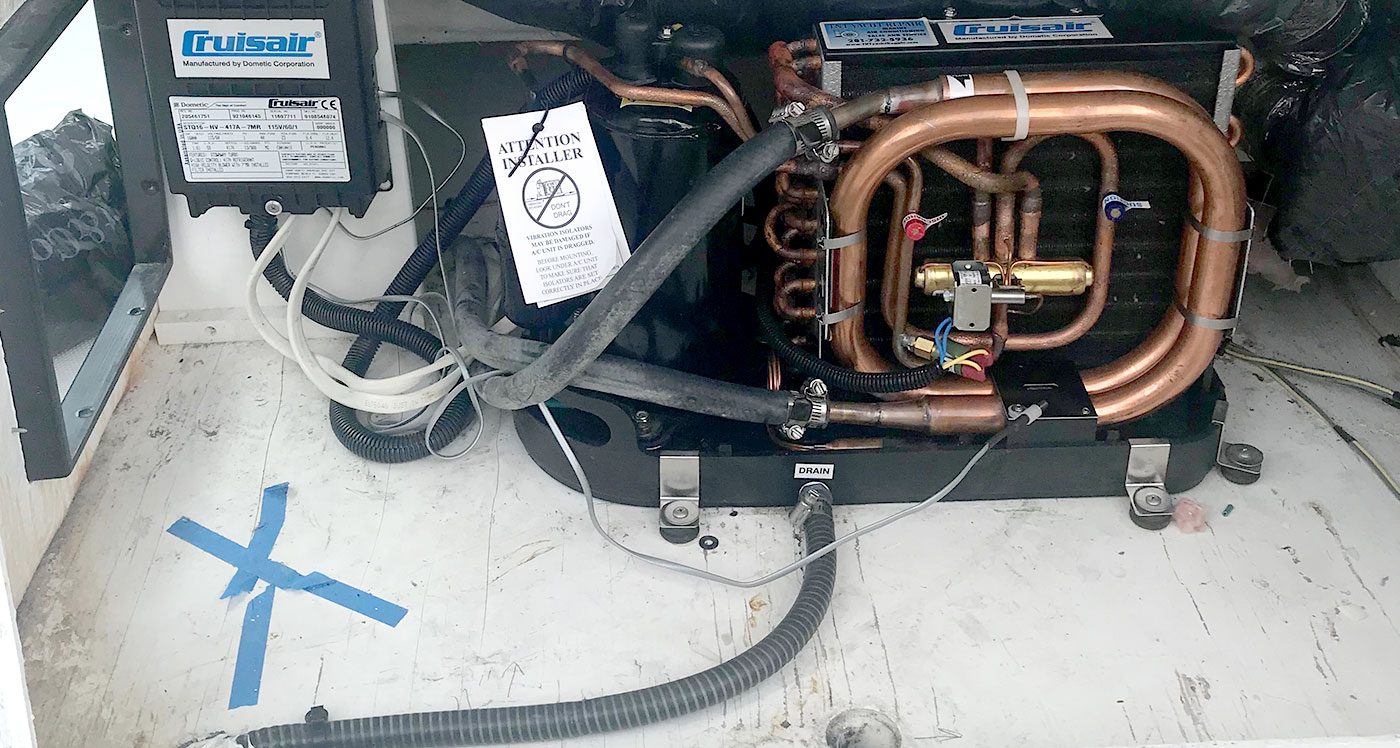

Before and After photos of AC jobs:

We Also Sell New Marine AC and Refrigeration Equipment.

Contact us NOW if you have need of our sales or repair services. Call 281-732-5936 or email us. We accept ALL Major Credit Cards and offer 24/7 Emergency After Hours service for an additional charge.